Doubts and Solutions

OR

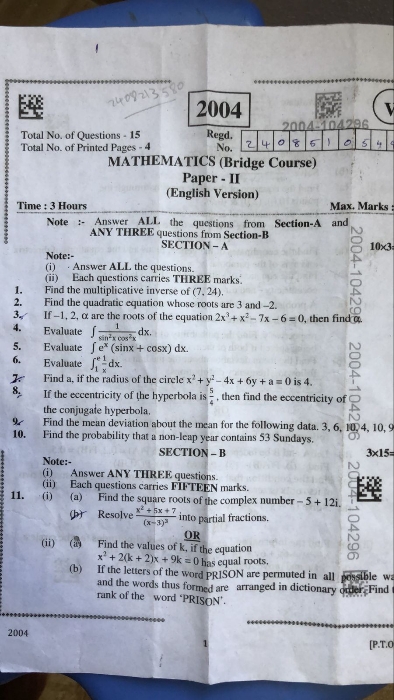

ICSE IX - Maths

Asked by jatinderkaur19852008 | 25 Apr, 2024, 06:25: PM

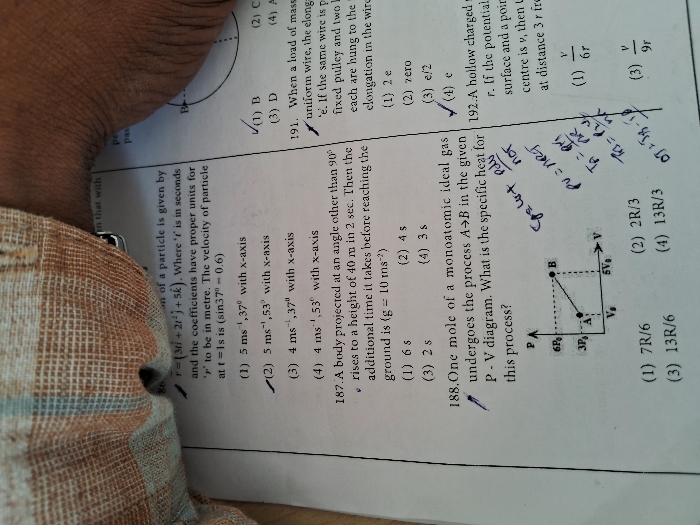

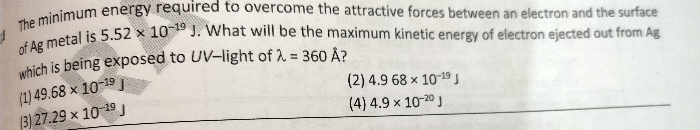

NEET NEET - Physics

Asked by ramanjaneyuluoguru | 25 Apr, 2024, 04:18: PM

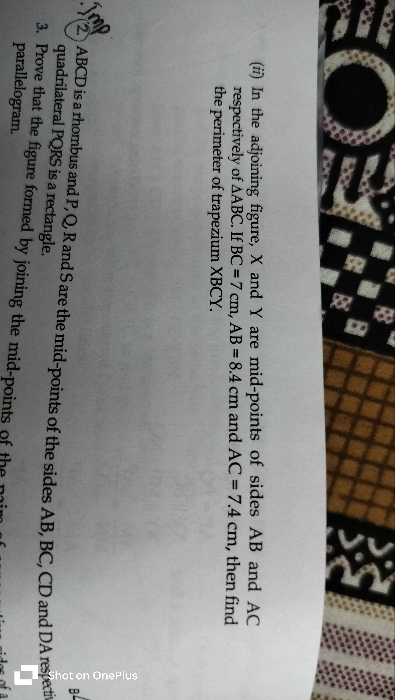

CBSE X - Maths

Asked by raopaidi | 25 Apr, 2024, 04:06: PM

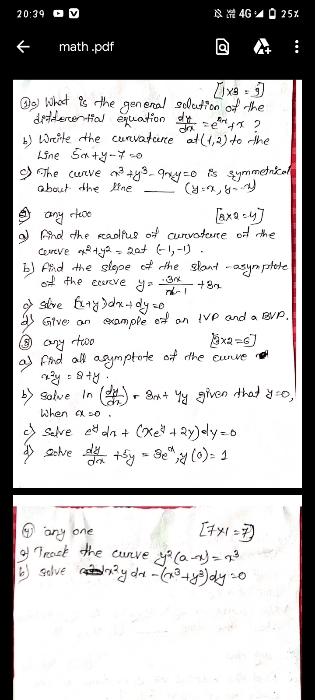

CBSE XII Science - Maths

Asked by leelasri11663 | 25 Apr, 2024, 11:34: AM

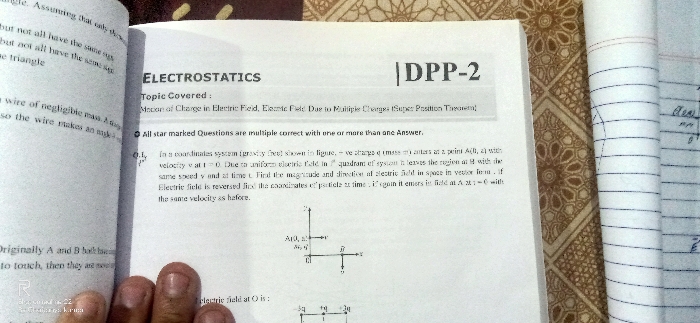

CBSE XI Science - Chemistry

Asked by saranyachakraborty2007 | 25 Apr, 2024, 05:23: AM

CBSE XII Science - Maths

Asked by aishaazmata | 24 Apr, 2024, 08:48: PM

ICSE VIII - History and Civics

Asked by khatunrafika276 | 24 Apr, 2024, 06:57: PM